When you admire the golden shine of a jewelry ring or the sleek black finish of a luxury bag clasp, have you ever wondered—what makes these colors and finishes possible?

Behind the beauty lies an unsung hero: the PVD target.

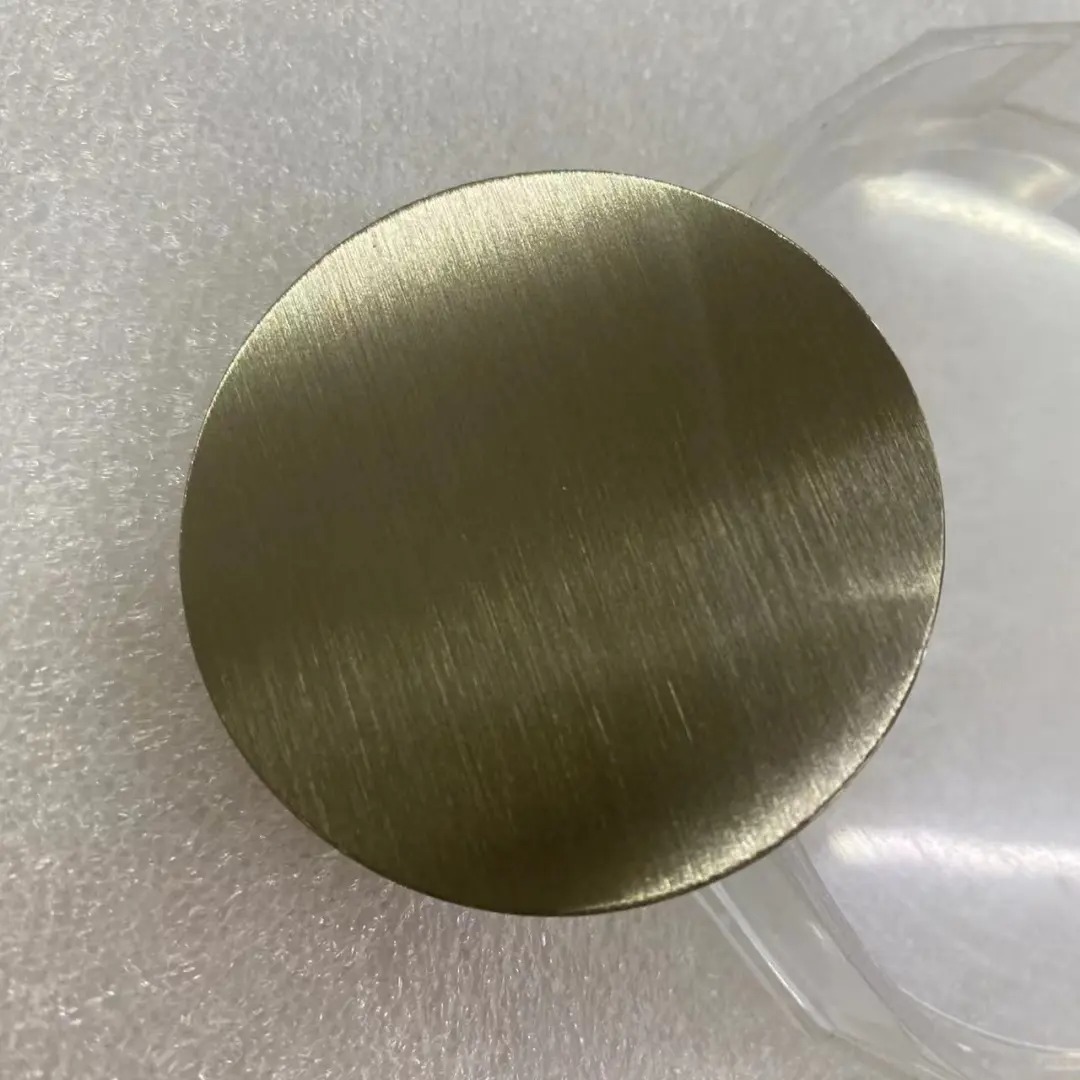

In Physical Vapor Deposition (PVD), a “target” is the raw material placed inside the coating chamber. Under high energy—through processes such as arc evaporation or magnetron sputtering—atoms from the target are ejected and deposited onto the product surface, forming a thin, decorative, and highly durable coating.

In short, the target defines the coating.

Reaction with Gases: When reactive gases like nitrogen, carbon, or oxygen are introduced, the metal atoms from the target combine to form nitrides, carbides, or oxides. For example:

Ti + N₂ → TiN (gold color)

Zr + N₂ → ZrN (pale gold)

Ti + C + N₂ → TiCN (gray to black)

Purity & Density: High-purity, dense targets ensure coatings with fewer defects, higher adhesion, and better corrosion resistance—critical for jewelry and hardware exposed to skin contact and daily wear.

Deposition Control: By adjusting parameters like power, pressure, and gas ratio, manufacturers can fine-tune coating thickness, hardness, and color tone.

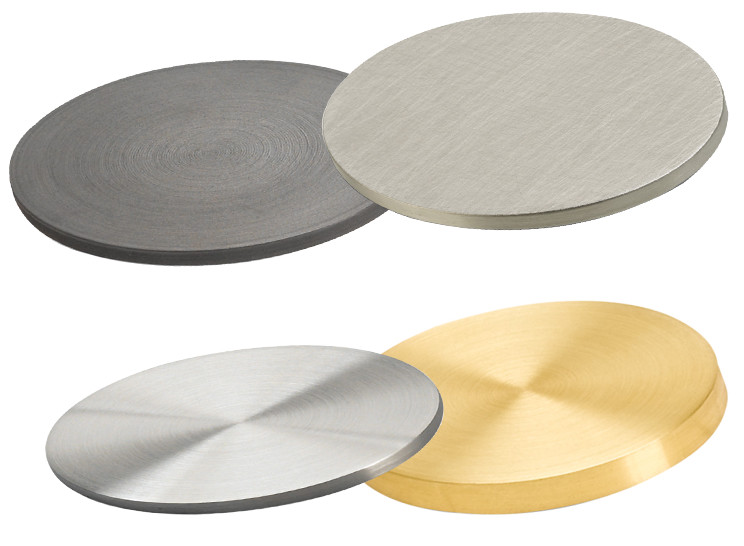

Different targets create different colors and properties:

Titanium (Ti): Classic gold, rainbow-like hues → used in rings, earrings, pendants

Zirconium (Zr): Black, dark gray → favored for men’s jewelry, bag clasps, zipper pulls

Chromium (Cr): Bright silver, strong corrosion resistance → bracelet locks, watch parts

Alloys & Precious Metals (Au, Pt): Premium finishes for high-end customization

Compound Targets (TiN, TiCN, ZrN): Hard coatings with unique tones → chains, buckles

For both jewelry and hardware, the target determines:

Color → fashion-forward finishes from gold to rainbow

Durability → resistance against scratching and abrasion

Corrosion Resistance → protection against sweat, humidity, and daily exposure

Brand Value → flawless surfaces that elevate craftsmanship and trust

At Yibi, we combine technical expertise with creative craftsmanship. By selecting the right PVD targets and controlling deposition parameters, we deliver coatings that are both visually stunning and engineered for long-term durability.

From rings, pendants, and earrings to bag clasps, zipper pulls, and chain links, our solutions meet the rigorous demands of luxury brands worldwide.

PVD targets may remain hidden inside the chamber, but they are the true foundation of every jewelry shine and hardware finish.

👉 Which PVD finish inspires you the most — classic gold, elegant black, or futuristic rainbow?