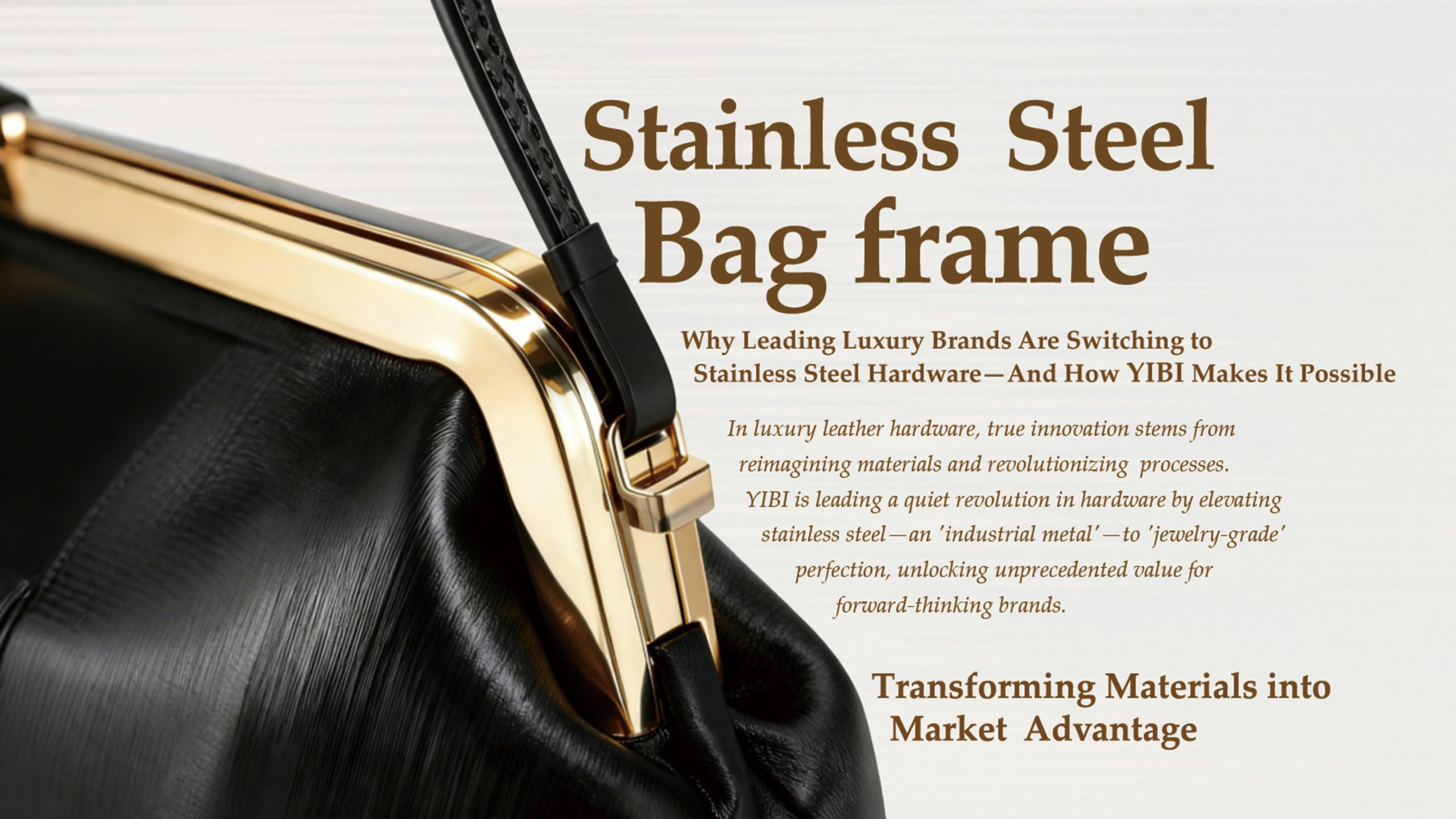

As luxury and premium accessory brands face rising expectations for durability, structural precision, and long-term quality stability, the leather goods hardware industry is undergoing a clear material shift. In the mid-to-high-end segment, functional components such as buckles, chains, zipper pulls, snap hooks, and especially bag frames (Bag Frames) are no longer treated as interchangeable metal parts. As a China Luxury Bag Frame Hardware Manufacturer, YIBI works closely with international brands navigating this transition, supporting the move from traditional alloys to engineered stainless steel solutions that deliver higher structural strength, consistent precision, and long-term performance for modern luxury handbags.

Today, brands are explicitly transitioning from traditional copper-based alloys and zinc alloys to stainless steel, seeking stronger structural performance, more stable surface behavior, and reduced long-term risk in daily use. In this transformation, YIBI positions itself as a high-end leather hardware manufacturer specializing in stainless steel materials, supporting premium brands with engineered hardware systems designed for modern luxury handbags.

For decades, brass and zinc alloy have been widely used in leather hardware due to their ease of casting and traditional weight perception. However, as bag sizes increase and usage scenarios diversify, the limitations of these materials are becoming increasingly evident.

Compared with stainless steel:

Copper-based alloys (brass)

Softer material structure, more prone to deformation under long-term mechanical stress

Susceptible to surface oxidation and discoloration, especially in humid or high-contact environments

Plating layers are more likely to wear or peel after extended use

Zinc alloy

Lower structural strength

Higher risk of cracking or distortion in large-format or load-bearing components

Less suitable for repeated opening-and-closing mechanisms

In contrast, stainless steel—especially 316L stainless steel—offers significantly higher tensile strength, superior corrosion resistance, and long-term dimensional stability. This makes it increasingly favored for hardware components that must maintain precision, alignment, and surface quality throughout the product lifecycle.

As a result, stainless steel is no longer viewed as a “material upgrade option,” but rather as a strategic choice for premium and luxury leather goods, particularly in structural hardware categories.

Among all leather hardware components, bag frames represent one of the most demanding applications. Unlike decorative buckles or logo plates, bag frames define the opening structure, closure precision, and long-term shape retention of a handbag.

In practical use, bag frames must withstand:

Thousands of opening and closing cycles

External pressure during travel and storage

The weight of larger bag bodies and internal contents

When manufactured with traditional alloys, bag frames are more likely to suffer from gradual deformation, misalignment, or inconsistent closure performance over time.

Compared with traditional deformation-prone metals, 316L stainless steel provides significantly higher structural strength, ensuring that large-format bag frames maintain precise alignment and tight closure even after long-term repeated use. This material stability helps ensure that the frame edges remain perfectly fitted, delivering the “clean closure feel” that luxury consumers expect.

For this reason, stainless steel bag frames are becoming the preferred solution for:

Large-capacity handbags

Structured fashion bags

Travel-oriented premium leather goods

Designs requiring slim profiles but high rigidity

YIBI is a high-end leather hardware manufacturer with a clear focus on stainless steel materials. Rather than offering mixed-material solutions, YIBI concentrates on engineering stainless steel components that meet the structural, aesthetic, and durability standards of premium leather brands.

The company specializes in OEM/ODM manufacturing of stainless steel hardware, including:

Bag frames (rigid and semi-rigid systems)

Chains and strap components

Buckles, clasps, and snap hooks

Zipper pulls and functional connectors

Coordinated stainless steel hardware sets

By focusing on stainless steel, YIBI supports brands that prioritize long-term quality consistency, structural reliability, and controlled surface performance, rather than short-term cost reduction.

Engineering Strength: Stainless Steel Bag Frames and Functional Hardware

Engineering Strength: Stainless Steel Bag Frames and Functional HardwareYIBI develops stainless steel bag frames with strict tolerance control, optimized hinge structures, and consistent surface finishing. These frames are designed to maintain dimensional accuracy and closure precision across extended usage cycles, even in large-size or heavy-use handbags.

To ensure visual and performance consistency, YIBI supplies complete stainless steel hardware sets—including frames, chains, buckles, and logo plates—allowing brands to maintain uniform tone, finish behavior, and tactile feel across multiple SKUs.

Stainless steel hardware offers:

Strong resistance to sweat, humidity, and corrosion

Reduced deformation risk under load

Stable surface performance with lower plating failure rates

These advantages directly reduce after-sales issues such as misalignment, surface wear, or functional complaints.

YIBI works closely with international brand teams through structured OEM/ODM workflows. From early-stage design evaluation to sampling, testing, and mass production, the company provides engineering-based feedback to ensure that stainless steel hardware designs are both aesthetically refined and structurally sound.

This approach is particularly valuable for bag frame development, where early material and structure decisions have long-term consequences for product quality and brand perception.

The transition from brass and zinc alloy to stainless steel represents more than a material change—it reflects a broader shift in how premium brands define quality, durability, and value.

With its focus on stainless steel materials and high-end leather hardware engineering, YIBI positions itself as a long-term manufacturing partner for brands seeking structural reliability, refined finishing, and consistent performance in luxury leather goods hardware.

For more information and business inquiries, visit YIBI Group on LinkedIn:

https://www.linkedin.com/company/yibi-group/