Why Does Hermès Prefer J3L, While Most Brands Stick with 316L?

In the field of jewelry and leather goods hardware, J3L and 316L each exert their unique material advantages, serving as key considerations for numerous brands in product development. They are not only the foundation for crafting exquisite jewelry and high-end leather goods and hardware but also profoundly influence product quality, durability, and aesthetics—capturing the attention of countless consumers. So, what makes these two materials so appealing? Why is Hermès so fond of J3L? And what enables 316L to maintain its dominant position in the market? Let’s delve into these questions.

Hermès, a brilliant star in the luxury goods industry, holds a special preference for J3L, and there are numerous in-depth reasons behind this choice.

J3L’s alloy composition is meticulously formulated, endowing it with outstanding corrosion resistance in various complex environments. During long-term contact with leather goods, oils, sweat, and various chemicals that may be encountered in daily use barely cause corrosion damage to J3L. Take Hermès’ classic handbags as an example—their hardware fittings, made of J3L, show almost no signs of rust or corrosion even after years of frequent use in humid conditions. In contrast, while 316L also offers a certain level of corrosion resistance, under the same harsh conditions, slight rust spots may appear on its surface over time, especially in crevices and edges where moisture and chemicals tend to accumulate.

J3L boasts remarkable strength, providing stable support for leather goods and ensuring they retain their original shape during long-term use. For some of Hermès’ large travel leather goods, the hardware fittings need to withstand significant tension and pressure—J3L components can easily handle this without deformation. At the same time, J3L possesses good toughness and is not prone to fracture when subjected to a certain degree of external impact. This feature makes Hermès’ leather goods more durable in daily use, reducing maintenance or replacement costs caused by damaged hardware. 316L’s strength and toughness are more suited to daily usage scenarios; its performance fully meets the regular stress requirements of most jewelry and leather goods hardware, though its deformation resistance is slightly inferior to J3L’s under conditions of long-term high-frequency stress or extreme use.

After precision processing, J3L exhibits a unique luster and texture—soft yet elegant luster, and a delicate yet solid feel. This distinctive surface effect perfectly aligns with Hermès’ brand philosophy of pursuing ultimate quality and high-end positioning, adding unique charm to its leather goods. When people touch the J3L hardware on Hermès leather goods, they can clearly perceive its distinctive texture, as if touching a meticulously crafted work of art. While 316L’s surface texture is already excellent among austenitic stainless steels after treatment, its luster and delicacy still cannot match J3L’s, failing to meet Hermès’ rigorous requirements for product texture.

From a brand strategic perspective, Hermès’ acquisition of J3L is a crucial move to strengthen supply chain control and quality management. By mastering J3L, Hermès can ensure the quality of hardware fittings from the source, producing and manufacturing them strictly in accordance with its own standards. This not only helps improve overall product quality but also enhances the brand’s competitiveness in the market. When facing market fluctuations and unstable raw material supply, Hermès can better guarantee production continuity and product consistency through its control over J3L, achieving sustainable development.

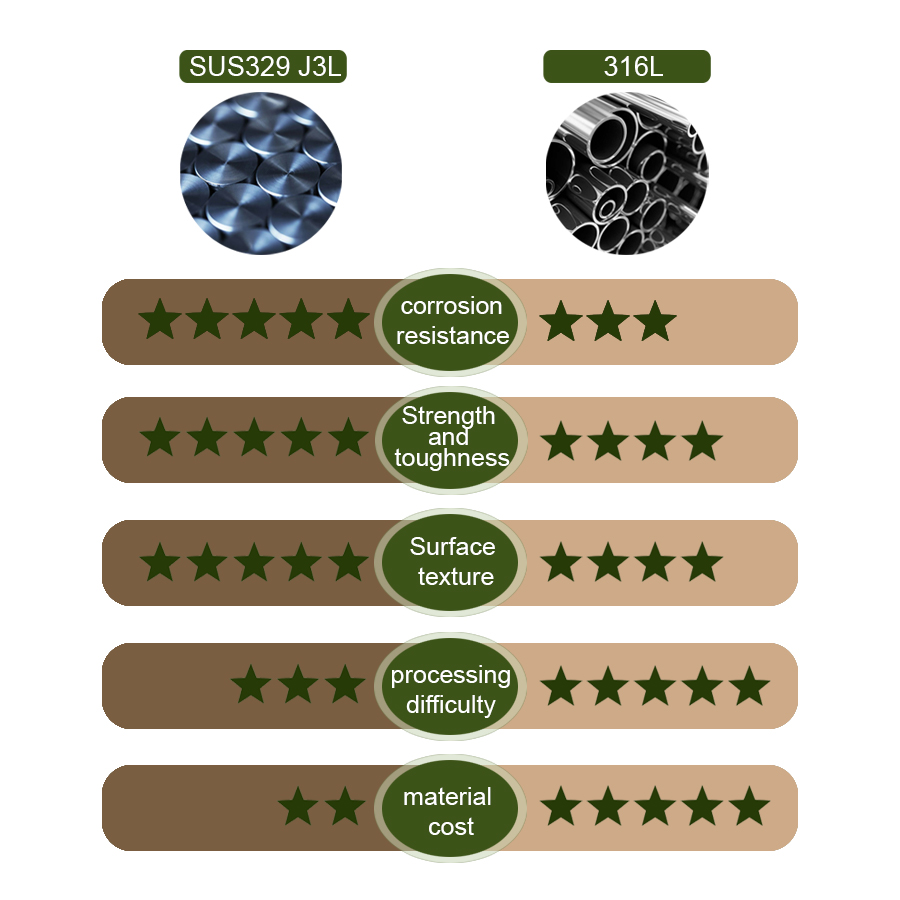

| Comparison Dimension | J3L | 316L |

| Corrosion Resistance | Extremely high—suitable for harsh environments like humidity and high salt | Good—meets daily conventional corrosion protection needs |

| Strength & Toughness | Excellent balance—outstanding deformation and fracture resistance | Suitable for daily stress; slightly weaker under extreme conditions |

| Surface Texture | Delicate and elegant—aligns with luxury brand positioning | Excellent performance—meets mainstream quality standards |

| Processing Difficulty | Higher—high cost for complex shapes | Lower—mature processes suitable for mass production |

| Overall Cost | Relatively high | Affordable—distinct cost-performance advantage |

Despite J3L’s outstanding performance in certain aspects, 316L still maintains a dominant position in the jewelry and leather goods hardware sector, driven by multiple in-depth reasons.

After long-term development and practice, 316L’s processing technology has become highly mature. From cutting, forming, and casting to surface treatment, each link has a complete and mature process flow and technical standards. In cutting, technologies such as plasma cutting and laser cutting can precisely process 316L to meet various complex shape requirements; in forming, processes like bending, rolling, and stamping can be completed efficiently while ensuring product precision and quality. Mature processing technology not only improves production efficiency but also reduces production costs and risks. For manufacturers, adopting mature processing technologies means better control over the production process, lower defect rates, and improved product consistency and stability.

316L enjoys widespread recognition and market acceptance among consumers and the industry. Consumers are familiar with the reliability and stability of 316L as a material for jewelry and leather goods hardware, trusting that it can meet daily usage needs. Many consumers prioritize 316L hardware when purchasing jewelry and leather goods, believing in its quality assurance. From an industry perspective, 316L has become an industry standard and consensus—major brands and manufacturers have grown accustomed to using 316L as hardware material in production. This widespread recognition and market acceptance form a stable market demand, securing 316L’s solid position in the market.

316L holds an advantage in terms of raw material acquisition and processing costs. Its raw materials are widely available with stable supply, resulting in relatively low raw material costs. Additionally, mature processing technology for 316L enables high production efficiency, further reducing processing costs. For mass-produced manufacturers, cost is a critical consideration. Using 316L as hardware material allows them to reduce production costs while ensuring product quality, enhancing product market competitiveness. In contrast, while J3L excels in performance, its complex production processes and higher raw material costs lead to a relatively high overall cost, which to some extent limits its application in mass production.

Looking ahead, with the continuous advancement of materials science, J3L is expected to achieve breakthroughs in production technology, thereby reducing costs and improving production efficiency. This will help J3L gain wider application among more jewelry and leather goods brands, further expanding its market share. As consumers’ pursuit of quality and uniqueness continues to grow, high-end brands focusing on quality and brand image may be more inclined to choose J3L as hardware material to enhance product competitiveness.

316L will not stand still either. In the future, it will continue to dominate the mid-to-low-end market. With technological development, 316L’s performance may be further improved—for example, enhancing its corrosion resistance and strength through modified alloy compositions and processing technologies. 316L may also find applications in emerging fields, such as hardware components for smart home devices as the smart home industry develops.

J3L and 316L each demonstrate unique advantages in the jewelry and leather goods hardware sector. Their application is not a simple material choice but a result of brands’ trade-offs across performance, cost, market recognition, and other factors. J3L, with its exceptional corrosion resistance, strength and toughness, unique surface texture, and strategic brand significance, has become a favorite of top luxury brands like Hermès, representing ultimate quality and unique charm. Meanwhile, 316L maintains its dominant position in the market by virtue of mature processing technology, wide recognition and market acceptance, and relatively affordable cost, meeting the mass market’s demand for cost-performance and stability.

As the times evolve, the future of these two materials is full of infinite possibilities. Whether it’s J3L pursuing superior quality or 316L emphasizing cost-performance, both will continue to write their brilliant chapters in the jewelry and leather goods hardware sector, bringing consumers more high-quality, aesthetically pleasing, and durable products.

J3L’s high-end performance caters to the quality pursuit of top brands like Hermès, while 316L’s cost-performance meets the mass production needs of mainstream brands. Essentially, the two materials are “optimal solutions for different positioning.” Whether choosing J3L’s high-end characteristics or 316L’s mainstream advantages, yibi can perfectly apply both materials to the production and manufacturing of jewelry and leather goods hardware, leveraging mature production technology and precise process control. Combined with core advantages such as leading processes like MIM (Metal Injection Molding) and PVD (Physical Vapor Deposition), yibi ensures J3L’s high-end texture and durability while maximizing 316L’s shape diversity and cost advantages—providing customized production solutions for brands of different positioning.